Turnkey Breweries (or “Brewhouses”) are comprised of several key pieces of beer brewing equipment. The mash tun, lauter tun, brew kettle, and whirlpool, in the hands of a skilled brewmaster, convert grain that has been milled through a specialty grain mill, into a sweet liquid called “wort”. Wort is then fermented and finished in specialized beer tanks called fermenters, lagering tanks and brite tanks.

The brewhouse is both the heart and engine of the brewery where several critical processes in the creation of craft beer and kombucha are performed. Turnkey breweries, along with other key pieces of brewing equipment, vary in capacity, features, and complexity, but all brewhouses share the need to wet grain, separate the wort from the grain, and boil the wort with a heating source. The three most common brewhouse heating sources are:

- Steam

- Indirect Fire

- Electric

Why Select a PKW Brewhouse?

Portland Kettle Works offers three turnkey brewery models including the popular…

- HopDiablo – 2 BBL capacity brewhouse (steam & direct fire)

- Hopmaster – 5 to 10 BBL capacity brewhouse (steam, indirect fire, & electric)

- BH Series – 7 to 30 BBL capacity brewhouse (steam & indirect fire)

Portland Kettle Works’ brewhouses have earned a reputation as some of the most consistent performing and eye-catching brewing equipment to be found anywhere. Our turnkey breweries will shorten your day while they save you money for years to come.

Portland Kettle Works’ brewhouses provide brewers with several key advantages:

- A worldwide reputation for industry-leading American design, engineering and fabrication

- Built with and tested by some of America’s leading craft brewers

- Environmentally friendly and energy saving

- Save Time and Labor

- Ergonomics and Safety

PKW Brewhouse Specifications

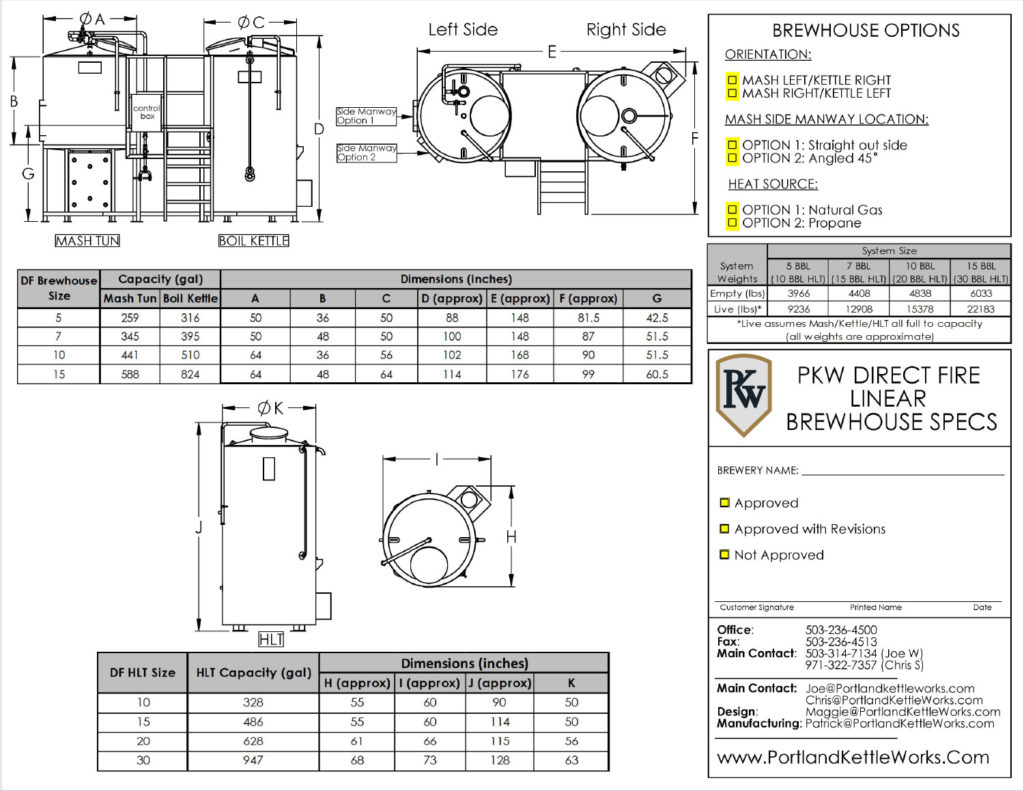

PKW Brewhouse Direct Fire (5 to 15 bbl) Spec Sheet

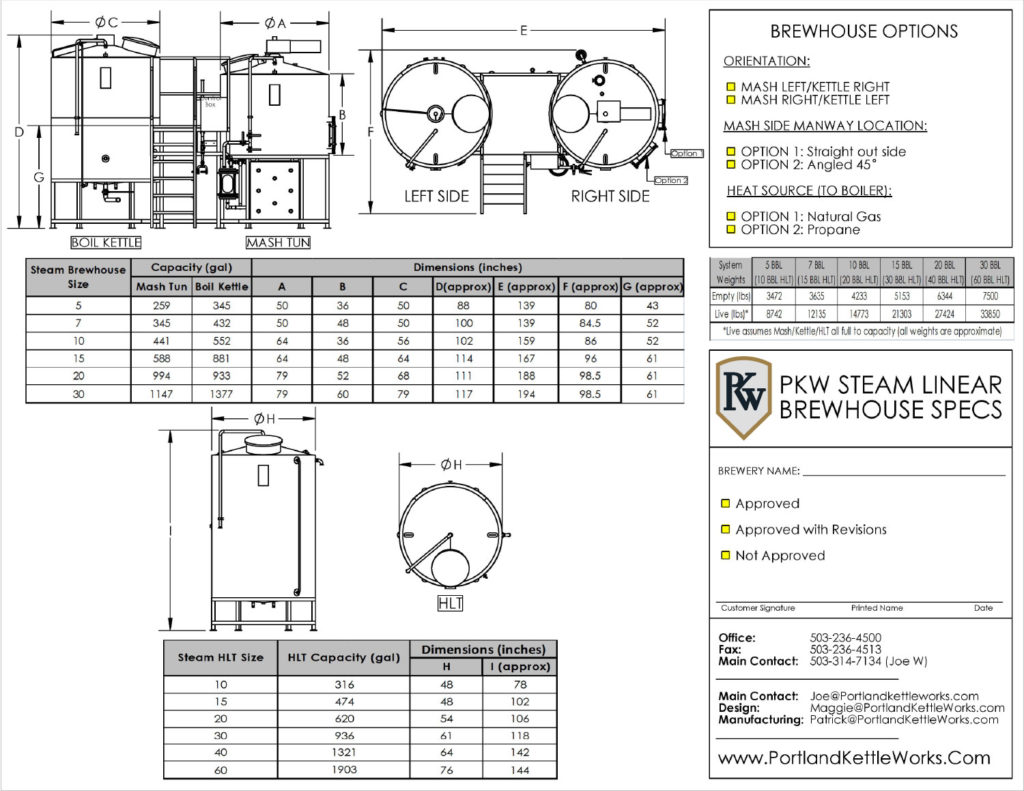

PKW Brewhouse Steam (5 to 30 bbl) Spec Sheet

As with all our brewing equipment, Portland Kettle Works brewhouses are designed and manufactured to exacting standards:

Capacities available:

- bbl: 2, 3.5, 5, 7, 10, 15, 20, and 30

- hL: 2.3, 4.1, 5.9, 8.2, 11.7, 17.6, 23.5, and 35.2

- Other capacities available upon request

Environmentally-friendly and energy-saving features:

- Extra-large capacity hot liquor tank (HLT) for ample storage and recovery of hot water in the brewery so that none of your heated water goes down the drain

- Convect-O-Matic proprietary internal calandria on the HLT continually agitates the HLT contents resulting in a consistent liquor temperature throughout the vessel without the use of an expensive and maintenance intensive pump

- State-of-the-art energy efficient motor drive systems are installed on every brewery pump motor reducing overloading and optimizing energy consumption to the pumping task

- Every brewery tank is insulated keeping the heat where it belongs, in the brew, not in the atmosphere

- 99% evacuation of evaporate from the brew kettle results in lower humidity and heat load in the brewery

- 12V LED lights are provided on all lighted elements for reduced energy consumption

Time and labor-saving features:

- Oversized HLT equates to zero downtime when double batching, running CIP, or performing keg cleaning operations

- Kettles and brew deck frame fabricated from 100% certified 304 food-grade stainless steel

- 3-piece modular design for easy installation in almost any space

- Brew kettle includes integrated whirlpool

- Brewhouses are pre-wired, pre-piped and pre-tested for easy shipping, rigging, installation, and startup

- Steam configurations fired by either electric or gas-powered boilers (direct fire options available)

- All steam-fired hot liquor tanks (HLT) and brew kettles equipped with PKW’s proprietary internal calandria

- All mechanical components provide infinite control and precise repetition to create an efficient brewing process

- Designed with features and geometry to diminish oxidation, tannins, and diacetyls

Ergonomics and safety features:

- PKW brewhouses are a breeze and pleasure to operate with no dead legs, redundancies or complicated processes to memorize

- Control panel access and brew decks designed to minimize fatigue and create a safer working space

- UL 508A-compliant electrical controls are accessible from the front of the brewhouse. Operators have immediate access to all functions including the system kill switch

- Non-skid surfaces provided on all operator work platforms

Portland Kettle Works was founded in 2011 to build the highest quality stainless steel brewing and beverage equipment applications. Since then we have built and installed over 300 breweries worldwide. Our craft brewers are among the best of the best and they have the gold, silver and bronze medals to prove it. If you’re serious about craft brewing as a business, contact us and we can help you, too. And if you’re located in Mexico or Latin America, click here to visit our Spanish language site.