Clean In Place (CIP) Systems

What Are Clean In Place (CIP) Systems?

Be green and save money at the same time. Clean In Place (CIP) systems automate the process of cleaning your mixing tanks.

CIP is more efficient than manual cleaning. With CIP you can “be green” and save time and money while significantly increasing safety, reducing water consumption, reusing caustic solvents and staying in total control of your tank cleaning operations.

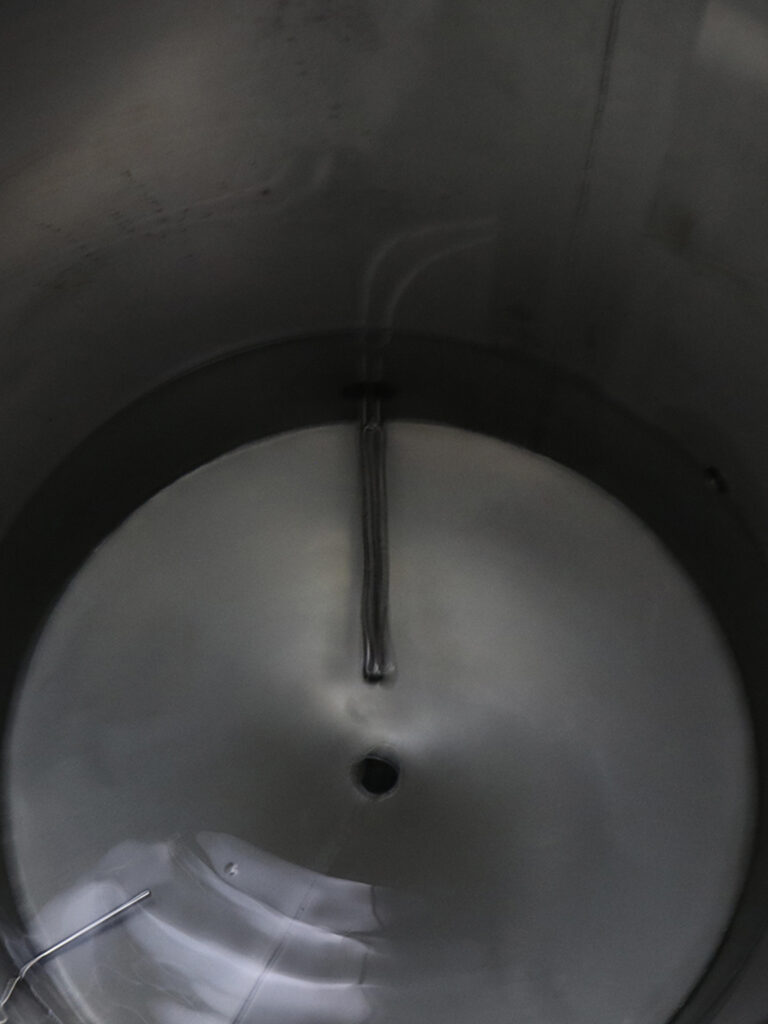

MTUSA Clean In Place (CIP) Systems clean and sanitize all internal surfaces of your equipment by pumping cleaning, rinsing, and sanitizing solutions over the same surfaces and through the same piping paths used by your product.

Stainless steel is ideal for mixing tanks with Clean In Place systems. Non-sticking, easy to clean, easy to sterilize and available in standard and custom sizes, Mixing Tanks USA specializes in stainless steel tanks – it’s all we do. If you need high-quality stainless steel mixing tanks with Clean In Place capability for your application – one, ten, one hundred or more – we can build them for you.

Advantages of Clean In Place (CIP) Systems

All Mixing Tank USA mixing tanks incorporating Clean In Place (CIP) systems can improve the operating efficiency of your content processing:

- Product Quality and Consistency: Regular, reliable and repeatable CIP cleaning means more consistent product quality.

- Environmentally Friendly: CIP systems minimize water usage and allow you to store and reuse caustic cleaning solvents.

- Minimize Errors: Automating CIP cleaning reduces the risk of human error that can result in contaminated products or hazardous factory conditions.

- Employee Safety: CIP reduces the risk of employee exposure to toxic cleaning solutions during routine cleaning.

- Production Efficiency: With CIP less production time is lost to cleaning leaving more time available for you to produce more product.

- Cost Savings: CIP cycles are consistent to minimize water, cleaning solvent and energy usage.

The Clean In Place (CIP) Cleaning Cycle

CIP cleaning cycles are typically run after a brewing batch has been completed or when changing over the production line from one product to another.

While the exact steps, sequence, and duration of the CIP cleaning process can vary from one CIP system to another, some common steps in most CIP cleaning cycles include:

- Pre-Rinse: Wet pipes and interior surfaces of tanks. Rinse off loose residue.

- Caustic Wash: Wash surfaces with caustic liquid cleaning agent at 140°- 190° F.

- Final Rinse: Rinse all surfaces with clear water to remove caustic agent residue

- Sanitizing Rinse: Rinse with sanitizing agent to kill germs and prevent bacteria growth.

All steps of the CIP cleaning cycle are computer controlled and all times, temperatures, etc. can be varied according to your factory’s requirements to produce a consistent, sanitary equipment cleaning time after time.

MTUSA Clean In Place (CIP) systems can automatically safely clean your equipment and save you time and money so you can produce batch after batch of your best products.